The use of fly ash, coal slag, coal gangue, tailing slag, chemical slag or natural sand, sea mud, etc. (one or several kinds of the above raw materials) as the main raw materials, without high temperature calcination and manufacture of a new type of wall material called free brick.

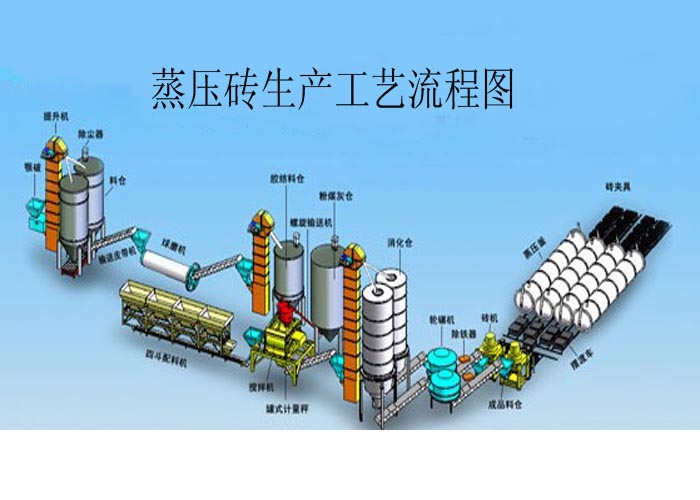

Autoclaved brick production equipment:

Multi-warehouse batching machine -- electronic batching and mixing building -- continuous digestion-type bin -- planetary wheel mill -- fully automatic hydraulic brick-making machine -- fully automatic billet stacking machine -- ferry car -- preconditioning room -- autoclave -- Finished product yard

Brief description of production process:

1. Store incoming raw materials separately

2. After measuring separately, add water to stir and digest, and the digested mixture is rolled by the wheel mill, and then sent to the brick press for pressure molding

3. The formed brick is put on the autoclaved trolley by the automatic billet stacking machine, and sent into the autoclaved kettle for steaming by the ferry car

4. After leaving the kettle, the finished product will be sent by the car to the finished product yard by the automatic brick unloader. After storage, it can be inspected and released

5. The empty autoclaved trolley shall be returned to the brick machine for reuse after cleaning

Tel: 0086-371-87091886

Fax:0086-371-87091887

E-mail:zzbona@zzbona.com

Copyright @ Bona enterprise. All rights reserved. Site Index Product Index

Design & Development by sinoart