Full-automatic hydraulic molding machine

-----Advantages analysis of brick machine between downstroke press type and upward press type

1.Pressure mode

Downstroke pressure cylinder at the bottom of the machine is installed in the pit which can ensure the safe operation of the brick machine. The structure of downstroke press type blocking making machine can ensure that the pressure punch can always move in the mold cavity up and down, and it can also keep the compression face above the wear proof mould lining board. If the compression face above is unavailable, the machine can turn the mould upside down and continue using the wear proof lining board.

Downstroke pressure cylinder at the bottom of the machine is installed in the pit which can ensure the safe operation of the brick machine. The structure of downstroke press type blocking making machine can ensure that the pressure punch can always move in the mold cavity up and down, and it can also keep the compression face above the wear proof mould lining board. If the compression face above is unavailable, the machine can turn the mould upside down and continue using the wear proof lining board.

Upward press type cylinder on the top of the machine has a punch above the mold which exits potential security risks when the machine is in the process of operation and maintenance. If the compression face above is unavailable, the machine can not turn the mold upside down so that the wear proof lining board can not be used continuously. The working life of the downstroke pressure type mode is twice as long as that of the upward press mold.

Upward press type cylinder on the top of the machine has a punch above the mold which exits potential security risks when the machine is in the process of operation and maintenance. If the compression face above is unavailable, the machine can not turn the mold upside down so that the wear proof lining board can not be used continuously. The working life of the downstroke pressure type mode is twice as long as that of the upward press mold.

2.Frame

The press is featured by the frame of locked prestress pull rod with three beams and four pillars, which guarantees the stability of the frame.

The upward press type machine is fastened with ordinary nuts.It gives rise to stress deformation of the frame in the process of pressing, which goes against the stability of running and the guiding precision of the working stand.

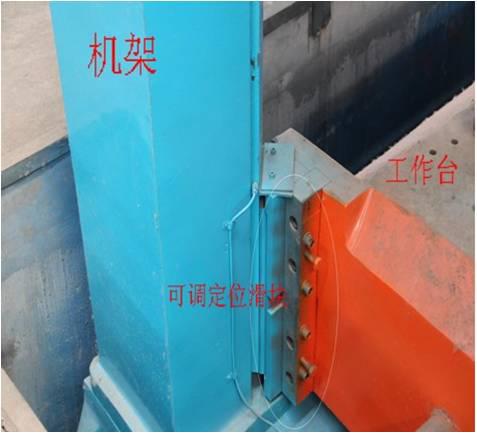

3. Oriented form of the operating platform

By using adjustable slider as oriented form, the machine frame of downstroke pressure and the operating platform enjoy high guide precision, easy lubrication and adjustable clearance. It can always ensure the orientation accuracy.

The upward press type machine using fixed sliding can not adjust the oriented clearance so that it can not compensate for the wear. It leads to a significant drop in guidance precision. So it is easy to damage the mold and broke the core rod when the pressure head falling fast.

4.hydraulic system

Our hydraulic system adopts the integrated valve block and centralized distribution. It has high hydraulic efficiency, less external oil, and low noise pollution.

The hydraulic system of the upward press type machine is made of hydraulic block which has scattered layout, outer pipe lines, larger hydraulic resistance, lower efficiency and severe hydraulic oil heating. And the design can lead to leak easily.

The main oil pump of the hydraulic system is Rexroth drive-by-wire variable displacement hydraulic pump with the advantages of large swept volume, quick response, low noise, stepless adjustment to pressure and flow and power saving. Rexroth hydraulic proportion valve has the advantage of quick response, low flowed friction, precise positioning, smooth operation without impact, and small heat, which guarantees the stable operation of the press.. The hydraulic technology of Germany Bosch Rexroth is the top brand globally, followed by USA and Japan.

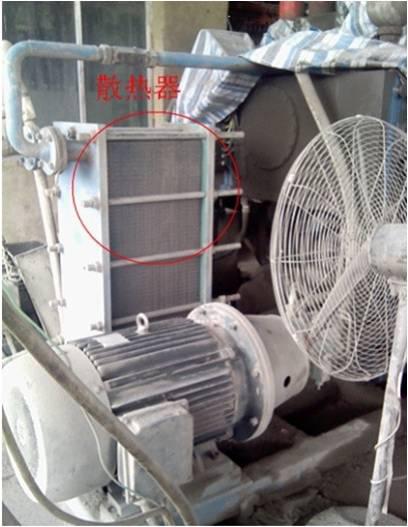

5.The hydraulic cooling system

6.Control system

Our control system adopts the Germany Siemens S7 logic digital controller and fully sealed temperature controlled air conditioning cupboard which effectively guarantees stable operation of the CPU and makes host system stable and reliable.

The general electric control cabinet is of bad air-proof and electrical components are easily polluted by dusts. It is bad for the heat dissipation of CPU at the same time it is easy to produce dust electrostatic interference which leads to the instability of program and the accident.

7.Electric control system operating software

Our electric control system adopts German Siemens S7 logic digital controller and automatic closed-loop control to intelligently adjust pressure, depth of filling, pressing speed which can automatically adapt to material uniformity and moisture content.

Upward press type electric control system for the open loop control need to manually adjust the speed, depth of filling and pressure. If material uniformity and moisture content change, it need artificial adjustment which increases the operator tension and affects the continuous production.

8.Type of distributor

Composite distributor is our company's patented technology, vibrated strengthening distribute form can make the materials more uniform which will also make the qualification rate up to 100%, and the quality more stable.

The upwards press type machine only press distributor which can cause material around the mould nonuniform,decrease the intensity of brick and rate of finished products.

9.The change of the mold

Our press adopts side type to change mold. It don’t need to take apart other auxiliary equipment when replacing the mold. Besides, this kind of design has push-pull cylinders which can make the change more convenient so that the changing time can be controlled in an hour.

Upward press type machine adopts front type to change the mold which need to take apart the belt machine. The machine need artificial tear open outfit and the intensity of labor is big. When the mold is installed, it still need to adjust positioning belt calibration which is time consuming and troublesome. It takes almost one day to complete the change.

10.Charging car hand clamping

We adopt Germany technology attain“muti-purpose for single hand.For different specifications of brick,it is not need to replace the clamping furthermore which is reliable and wear-resistant.”

Upward pressure clip hand belongs to airbag clip hand which is single function that only be suitable for one kind of specification. And that, airbag clip hand features aging, loss of elasticity, and be difficult in reseting. Besides, the state of uneven fabric, mould damage occurs frequently when brick need to be back to cavity.

11.Setting machine

The electric motor of our setting machine is Germany servo motor. The German SEW servo motor is featured with closed loop control, with advantages of high precision, accurate position, high speed, safety and reliability. The adobe can accomplish two-direction merger, cross stacking between layers, 90 degree rotation or single rotation on both ends.

Other pressing machines are featured by frequency conversion control with poor stability, which is inferior to servo control, and has the tendency to be susceptible to interference and lose control, giving rise t a few domestic human injuries.

12.The design of materials recycling

Our machine is equipped with a device for materials recycling. This design is to recycle the defective materials in the process of functioning. There will reserve some space for the device before the installation of the machine.

There are no space for upward press type brick machine to recycle the defective materials. So the materials will adhere to the surface of the machine and it will affect the environment of the operating.

13.Brush of belt conveyor

.jpg)

The surface of downstroke press type brick machine is clean without brush to clean up.

There maybe a lot of defective material on the surface of upward press type brick machine so that it lead to more material losses and labor intensity.

14.The shape of bricks

With it advantages down-stroke type press machine can produces standard bricks, blind hole brick, hollow brick, small block and other heterotypic bricks.

The upward press type brick machine have the punch above the mold. Due to forming principles and the type of taking out molds, it can only make standard bricks.

Tel: 0086-371-87091886

Fax:0086-371-87091887

E-mail:zzbona@zzbona.com

Copyright @ Bona enterprise. All rights reserved. Site Index Product Index

Design & Development by sinoart